27 YEARS OF FORMULA & KTM

This year, Formula celebrates 27 years of partnership with KTM.

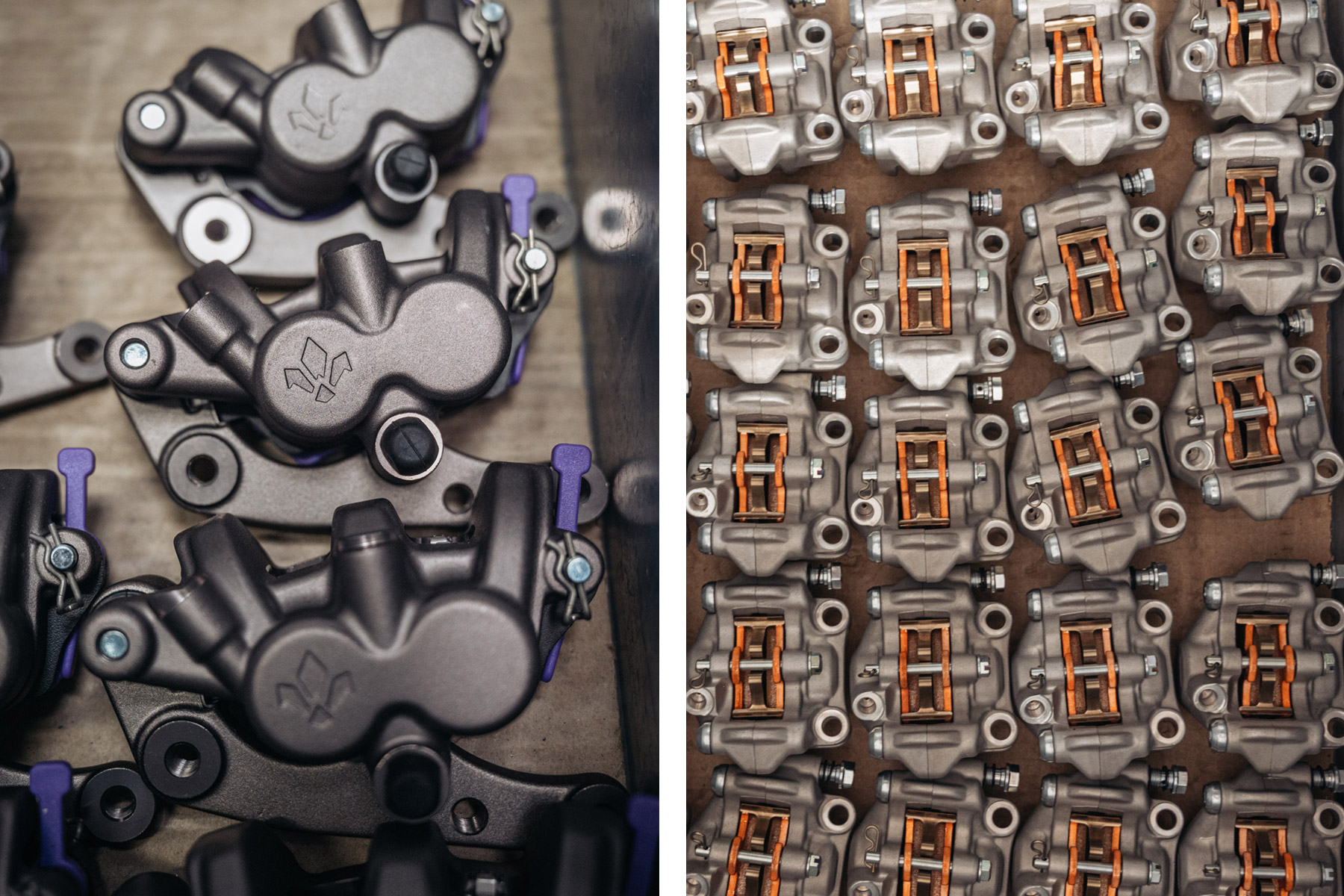

Together, we have developed braking systems that are OEM fitments on KTM, Husqvarna, and GasGas youth motocross bikes.

BEGINNINGS

In 1999, KTM approached Formula to help improve the brake systems of their youth motocross bikes.

The first product was a front brake caliper for KTM’s 65cc motocross bike, which combined Formula’s mountain bike and motorcycle technologies. A complete brake system for the smaller 50cc model followed soon after.

Within three years, Formula was producing full brake systems for KTM’s 65cc and 85cc bikes.

FORGING AHEAD

Initially, Formula sourced components for these braking systems from European suppliers. However, after Formula’s engineers developed an innovative casting process, a forge was built at their factory in Tuscany, allowing them to manufacture brake calipers in-house.

This casting process used molten metal with a thicker consistency than usual. The metal, resembling the texture of toothpaste, was slowly drawn into molds, reducing the air in the mixture, and resulting in stronger, more durable brake components.

This advancement allowed the calipers to be used on larger capacity bikes within KTM’s range, such as the 350 Freeride model.

MOVING EAST AND MOVING UP

Changes in the global economy and rising energy costs prompted Formula to once again source components from third parties, this time in Asia. To keep full control over the process, Formula set up a subsidiary factory in Taiwan.

This allowed for the use of forged aluminum components in the brake systems, aligning with the KTM Group’s desire to apply “big bike” technology to their youth motocross range.

Floating axial, dual-piston calipers were introduced to KTM’s 65cc and 85cc models. The master cylinder and caliper designs evolved to provide youth riders with braking performance and feel equivalent to that found on adult motorcycles.

THE EVOLUTION OF THE PROCESS

As production volumes increased, Formula and KTM worked together to refine both pre-production and production procedures.

The pre-production phase encompasses concept definition, design, prototyping, testing, and sampling, using a combination of desktop software, 3D printing, and prototyping.

The production workflow focuses on risk management, quality control, and on-time delivery. Formula follows a Control Plan, conducts Failure Mode and Effects Analysis (FMEA) reports, tests material composition through the International Material Data System, and implements Non-Conformity and 8D defect reports.

Post-production, Formula’s Technical Department collaborates with KTM on end-user documentation and regulatory compliance.

CHAMPIONS

Formula has supported up and coming riders such as Andrea Uccellini, who took his Formula-equipped Husqvarna TC 85 to victory in the 2024 Italian 85cc Motocross Championship – proof of a successful partnership in both business and competition.

You can see the brakes in action and read Andrea’s feedback on the product HERE.

Formula is proud of its strong relationship with KTM and looks forward to continuing to build on this partnership.